Education, preparation, and ongoing evaluation are the keys to implementing an effective hazmat containment plan.

Hazardous materials (hazmat) are substances that, by their very nature, can pose a significant risk to human health and the environment. When such materials spill or leak, swift and effective containment is crucial to prevent these risks from escalating. This comprehensive guide will outline the most common strategies for hazmat containment, offering insights into when and how to use them.

Understanding Hazmat Containment

Before we plunge into containment methods, it's essential to grasp why containment is necessary. Hazmat can include a wide range of substances, from industrial chemicals to radioactive materials. When they escape their designated containers, they can contaminate the air, water, soil, and even food supplies. Immediate containment not only mitigates these dangers but also makes subsequent clean-up efforts more manageable and less costly.

The Four Pillars of Effective Containment

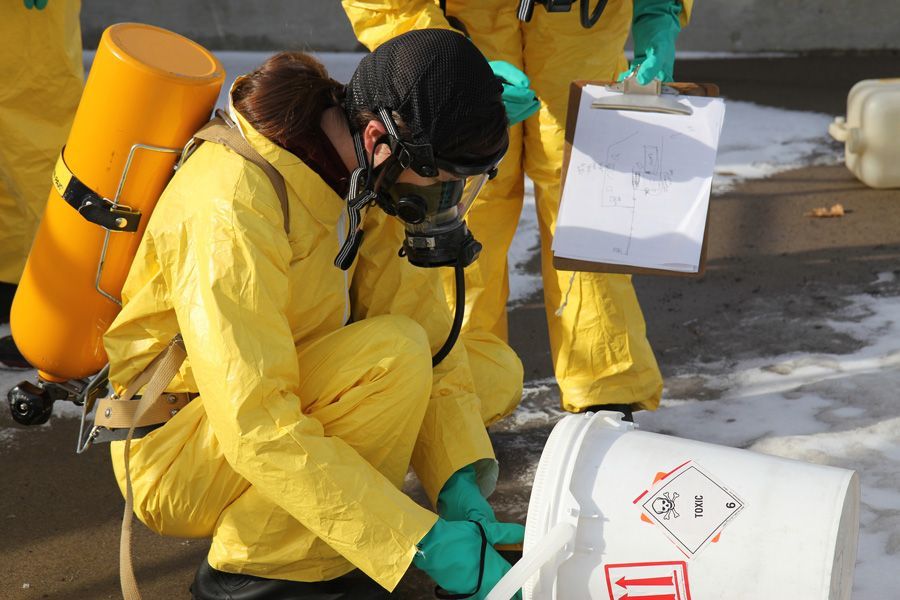

- Recognizing the Threat: Proper training and clear communication are critical for identifying potential hazards and initiating the correct containment procedures.

- Rapid Deployment: When a spill occurs, response time is of the essence. Having a pre-established plan and the necessary resources is key to containment success.

- Material-Specific Approach: Different hazardous materials require different containment methods. Neutralizing a chemical spill, for example, demands a different approach than containing an oil spill.

- Preventing Escalation: An effective containment strategy ensures that the spill doesn't grow worse, typically through physical barriers or neutralization methods.

Containment Methods: An In-Depth Review

Several techniques can be deployed to contain a hazmat spill. Below, we'll explore the most widely used methods and the scenarios in which they excel.

Absorbents

When to Use: Absorbents, such as mats, socks, and particulates, are ideal for liquids like oil, gasoline, and chemical solvents. Once the absorbent material is saturated, it should be properly disposed of as hazardous waste.

Types of Absorbents

- Universal Absorbents: These are effective against most non-aggressive liquids and are a versatile addition to your hazmat kit.

- Oil-Only Absorbents: Designed to repel water while absorbing oils and other hydrocarbons, these are perfect for hydrophobic liquid spills on water or in wet environments.

- Chemical Absorbents: These are resistant to chemicals and are designed for aggressive liquid spills, such as those involving strong acids or bases.

- Hazardous Waste Absorbents: For spills involving hazardous waste materials, special absorbents designed to encapsulate the waste and allow for safe disposal are required.

Diking

When to Use: Diking involves constructing a barrier using dirt, sandbags, or a purpose-built kit to stop the spread of the spill. It's effective for containing larger spills, particularly those involving corrosive or flammable liquids, to prevent them from reaching nearby waterways or other sensitive areas.

Tips for Effective Diking

- Assess the Size of the Spill: Ensure the dike is large enough to contain the entire volume of the spill.

- Utilize Natural Barriers: If possible, make use of the terrain's natural features, such as ditches or berms, to minimize the need for additional dike materials.

- Plan for Runoff: Contain and dispose of any hazardous runoff separately.

Neutralization

When to Use: Neutralization is the process of chemically treating a spill with a substance that, when combined with the hazardous material, renders it less harmful. This method is reserved for chemical spills, particularly those involving acids or bases.

Common Neutralizing Agents

- Acids: For alkaline spills, the introduction of a weak acid can neutralize the base and reduce its reactivity.

- Bases: In the case of acid spills, bases like soda ash or sodium bicarbonate can help neutralize the acidity of the spilled material.

Evacuation

When to Use: In scenarios where the spill poses immediate health risks, such as toxic fumes or a fire hazard, the immediate area should be evacuated to ensure the safety of individuals.

Evacuation Best Practices

- Establish Clear Evacuation Routes: Well-lit, clear, and unobstructed routes should be designated for immediate evacuation.

- Account for All Personnel: A headcount and roll call should follow an evacuation to confirm the safe removal of all individuals from the area.

- Regroup in a Safe Area: Once evacuated, employees should regroup in a designated safe area to receive further instructions.

Developing a Comprehensive Hazardous Material Containment Plan

No two spills are identical, which is why a one-size-fits-all approach to containment is ineffective. Your organization should have a custom hazmat containment plan that considers the type and quantity of materials that could potentially be spilled, the layout of your facilities, and the local environment.

Key Considerations for Plan Development

- Conduct Risk Assessments: Identifying potential spill risks and their likely impact is the first step in developing an effective plan.

- Invest in Training and Equipment: Proper training and access to the right containment tools are crucial for your team's ability to execute the plan effectively.

- Maintain Prepositioned Response Kits: Having readily accessible kits — complete with the necessary absorbents, safety gear, and neutralizing agents — can dramatically reduce response time.

Simulated Drills and Continuous Improvement

Just as with any emergency response plan, regular drills and debriefing sessions help to keep skills sharp and allow the team to identify areas for improvement.

The Legal and Environmental Ramifications of Improper Hazmat Containment

Failing to contain a hazardous material properly carries significant legal and environmental consequences. Pollution laws, such as the Clean Water Act and the Resource Conservation and Recovery Act, mandate strict guidelines for hazmat containment and spill response. Violations can lead to substantial fines, legal liability, and damage to the company's reputation.

Responding to the Aftermath of a Hazmat Spill

If a hazmat spill does occur, an organized and thorough clean-up effort is crucial. This may involve the use of more advanced techniques, such as vacuum systems for hazardous dusts, or the application of bioremediation for certain spilled substances, like oils.

Reporting and Documentation

Proper reporting of the spill, along with accurate documentation of the containment and clean-up actions, is essential for compliance and insurance purposes. The report should include the cause and nature of the spill, the quantity of material released, the containment method used, and any support provided to affected individuals or communities.

A Proactive Stance on Hazmat Containment

Rather than viewing hazmat containment as a reactive measure, organizations should adopt a proactive stance. This involves regular maintenance of storage containers, training to identify and handle potential spill sources, and the ongoing improvement of containment strategies.

The Role of Technology in Proactive Containment

Advancements such as remote monitoring systems that alert staff to changes in storage vessel pressure or temperature can provide a crucial early warning of potential hazards. Similarly, drones equipped with cameras can help assess the extent of a spill without risking human safety.

Conclusion

Hazmat containment strategies are the frontline defense against environmental disasters and the ensuing fallout. By understanding the types of containment methods available and when to employ them, organizations can be better prepared to respond to spills in a way that protects both their workers and the world around them. Education, preparation, and ongoing evaluation are the keys to implementing an effective hazmat containment plan. Remember, containment isn't just about preventing the spread of a spill; it's about safeguarding our shared environments for generations to come.